E-fuel pilot

E-fuel Pilot Project:

Innovative and cost-efficient production process for Power-to-Liquid using industrial off-gases

E-Fuel Pilot (Project ID: 101132987) is an ongoing project by Nordic Electrofuel, co-funded by the European Union through the Innovation Fund with a grant of €40,000,000. This support highlights the project’s strategic importance in advancing Europe’s climate goals and enables Nordic Electrofuel to pioneer sustainable e-fuel production for the aviation sector.

The E-Fuel Pilot project aims to establish and operate a first-of-its-kind synthetic fuel production plant, also referred to as E-fuel 1, at Herøya, Norway. The project focuses on developing an innovative and cost-efficient Power-to-Liquid (PtL) process that uses industrial off-gases as the carbon source. It will demonstrate the ability of the Power-to-X (P2X) concept to decarbonize heavy industry by turning hard-to-abate emissions into circular carbon products.

At the core of the project is Nordic Electrofuel’s (NELF) patented P2X production process. Our technology represents a breakthrough in flexibility, reliability, and simplicity. It is designed to achieve very high energy efficiency, with carbon utilisation close to 100%. The carbon used in the process is captured from a local point source, but the technology is also suitable for other CO or CO₂ sources such as metal production, cement production, or waste incineration. This allows decarbonization of various hard-to-abate emissions on an industrial scale.

The process combines reversed water gas shift (RWGS) and Fischer-Tropsch (FT) technologies to produce approximately 8,000 tonnes per year of synthetic hydrocarbons (syncrude). We implement established technologies with innovative approaches to achieve greater efficiency and eliminate the requirement for a catalyst in certain stages of the process chain. As a result, we are able to produce e-fuels at reduced capital (CAPEX) and operational (OPEX) costs compared to current state-of-the-art projects. This also allows us to flexibly convert a range of carbon feedstocks with various compositions.

A significant environmental benefit of the E-Fuel Pilot project is the expected greenhouse gas (GHG) emission reduction. The project anticipates more than 99% relative GHG emission avoidance compared with the fossil-based reference scenario. Over the first 10 years of operation, the plant is expected to avoid 228,163 tonnes of CO₂-equivalent absolute emissions.

The synthetic fuels produced from the refined syncrude will replace fossil-based products in aviation and other hard-to-abate sectors. These fuels can be used directly in existing engines and infrastructure without requiring modifications. In addition, syncrude-based kerosene provides significantly cleaner combustion, reducing particulate emissions and helping to limit the formation of cirrus clouds, which are known to intensify global warming.

Beyond the environmental impact, the project will generate substantial socio-economic benefits. It is expected to create around 270 direct jobs and an estimated 700 indirect jobs, including roles in engineering and related activities. Regionally, the project will contribute positively to economic development and industrial activity.

The E-Fuel Pilot aligns with key European and national policy objectives. It supports the REPowerEU goal of reducing fossil fuel consumption in both industry and transport sectors, while also contributing to the decarbonisation targets of the REFuelEU Aviation and FuelEU Maritime initiatives. More broadly, the project advances overall efforts to decarbonise aviation and maritime transport.

Following the successful demonstration of technical and economic feasibility at the pilot scale, the next planned step is a facility with significantly increase production volume and further technological innovations, building on the learnings from the pilot.

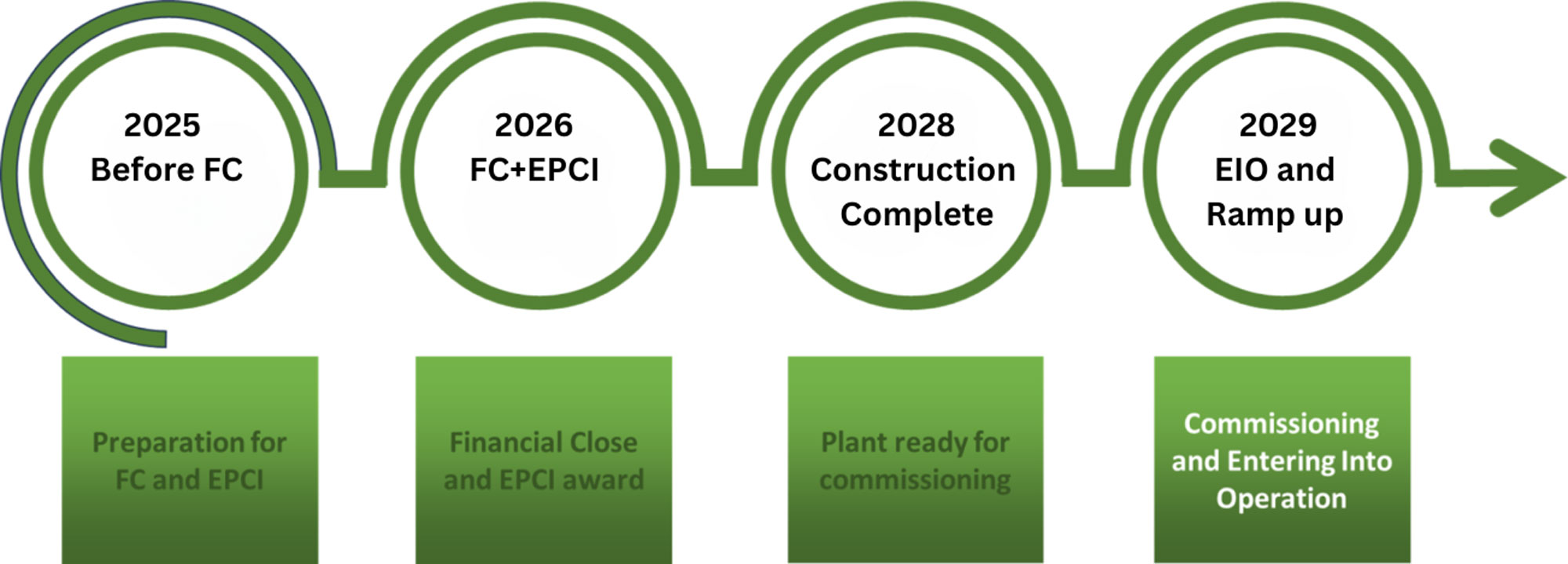

Project status

Innovative and cost-efficient production process for Power-to-Liquid using industrial off-gases