Our mission

Nordic Electrofuel will utilize renewable electricity, hydrogen, and CO2 to produce Sustainable Aviation Fuel (SAF). We aim to provide a scalable and viable solution for decarbonizing aviation.

Grant agreement with the European Climate, Infrastructure and Environment Executive Agency (CINEA)

Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the Emission Trading System Innovation Fund. Neither the European Union nor the granting authority can be held responsible for them.

Research & Development

Our research and development provide the foundation for advancing e-fuel projects from early concepts towards future implementation and scale-up.

R&D activities focus on developing and validating integrated process concepts for the conversion of biogenic CO2 and other carbon sources into sustainable aviation fuels, addressing sectors where credible alternatives to fossil fuels remain limited.

A key element of an e-SAF production plant is the reactor used to prepare syngas, an essential intermediate in synthetic fuel production. Conventional reactor designs typically rely on catalytic technologies, which can face operational challenges leading to reduced uptime and conversion efficiency. Nordic Electrofuel has developed and patented a novel, two-zone, catalyst-free reactor concept, named SAFIRE, designed to address these challenges. SAFIRE gives you control where it matters most, inside the reaction!

Plants and projects

Our first plant is located at Herøya Industrial Park in Porsgrunn, Norway. The plant is named E-fuel1 and is designed for a yearly production capacity of 10 million litres of synthetic fuels. This will result in a reduction of the CO2 industrial footprint by 25,000 tonnes annually.

FAQ

1. What is Nordic Electrofuel and what problem do you solve?

Nordic Electrofuel pioneers the production of high-quality synthetic aviation fuels (e-SAF). By combining water, captured CO₂, and renewable electricity, we transform clean energy into “liquid electricity” — a scalable solution to decarbonize air travel.

Our CO2-neutral e-fuels are designed to meet the strict requirements of aviation: they are drop-in compatible with today’s aircraft and fueling infrastructure, offering airlines a practical solution to cut emissions and progress toward climate goals. With one of the lowest greenhouse gas intensities among fuel alternatives, our technology contributes to building a more sustainable future for the aviation.

2. How are synthetic e fuels produced, and why are they needed for aviation?

Synthetic e fuels are made by combining hydrogen — produced from water using renewable electricity — with captured CO₂ to create clean, drop-in fuels. They can be used in today’s aircraft engines and fueling infrastructure without modification.

Aviation cannot yet be fully electrified, as battery technology for long-haul flights is not available at the necessary scale. E-fuels provide a scalable solution today, enabling airlines to reduce emissions without waiting for new aircraft technologies.

Nordic Electrofuel is leading the way by building one of the world’s first commercial power-to-liquid hydrocarbon plants.

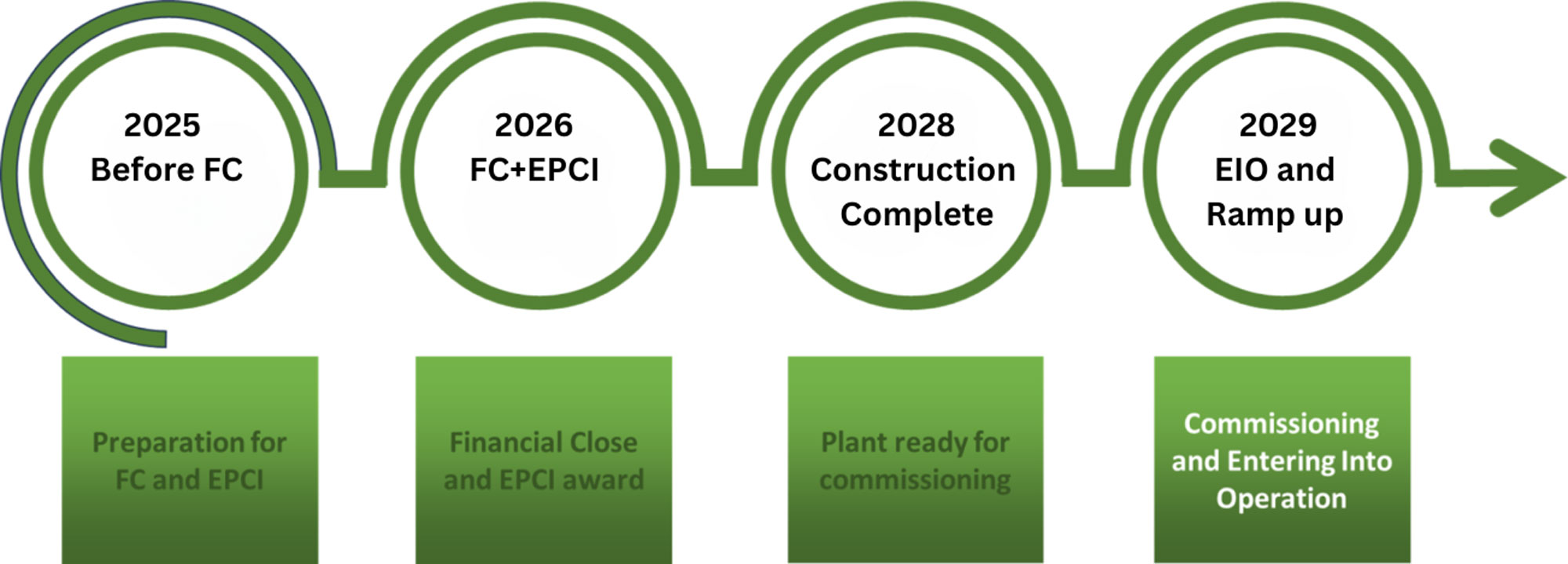

3. Where and when will you start production?

Set to begin operations in 2029, E-Fuel1, Nordic Electrofuel’s first plant at Herøya in Porsgrunn, Norway, represents a major step toward reducing aviation’s global carbon footprint.

This milestone project will not only supply sustainable jet fuel but also create a profitable new green industry and high-quality jobs in Norway. Looking ahead, we plan to build several similar plants to scale production and are proactively securing renewable power, water, CO₂, and land to meet growing demand.

4. What makes Nordic Electrofuel’s technology innovative and scalable?

• First of its kind: This will be the first industrial-scale e-plant producing synthetic liquid hydrocarbon-based fuel (rather than power-to-gas or power-to-methanol) from CO₂, water, and renewable electricity.

• Novel reactor and process: The conversion of CO₂ to hydrocarbon liquids is done in a non-catalytic oxygen promoted syngas reactor that combines conversion of CO2 to CO and reforming of tail gas from the Fischer-Tropsch reactor that is used to produce the liquid hydrocarbons. This gives a more efficient, flexible and robust plant and it significantly reduces both Capex and Opex. The syngas reactor is easy to scale at least 10 times from E-Fuel1 size.

• Electrolyser innovation: We use electrolysers that produce pure oxygen for the syngas reactor.

• Scalable Fischer-Tropsch process: The tubular fixed-bed Fischer-Tropsch reactors are the most mature, robust and flexible technology and are very easy to scale at least 10 times from E-Fuel1 size.

5. Why choose e-SAF over batteries or bio-SAF alternatives?

E-SAF (electro-sustainable aviation fuel) offers a realistic and immediate way to cut emissions in aviation. Some transport sectors especially aviation cannot switch to battery technology overnight due to the scale of energy storage required. E-SAF is a drop-in fuel that works in today’s aircraft and fueling infrastructure, meaning it can start reducing emissions right away. Compared to bio-SAF, e-SAF is produced from renewable electricity, water, and captured CO₂, making it fully scalable without relying on limited biomass resources. This makes it a reliable, environmentally friendly solution that supports the zero-emission goal and accelerates the green transition.

6. How does Nordic Electrofuel’s e-SAF fare in terms of emissions and compatibility?

According to the EU RED methodology, our e-SAF achieved a 90% reduction in GHG emissions compared to conventional fossil jet fuel*. The Fischer-Tropsch pathway utilized in our production process is fully certified under the ASTM D7566 standard for synthetic paraffinic kerosene (SPK). This certification enables customers to implement our solution seamlessly as a drop-in fuel, maintaining compatibility with their current fleet and infrastructure**.

* Based on COMMISSION DELEGATED REGULATION (EU) 2023/1185, defining the methodology for assessing GHG emissions for RFNBO to comply with mandatory blending mandates for synthetic aviation fuel defined under ReFuelEU Aviation.

** According to ASTM D7566 Annex A1, FT SPK can be used in blends up to 50%